This recipe is works http://ask.winnermicro.com/article/61.html

This recipe is works http://ask.winnermicro.com/article/61.html

Hi! We had a discussion about this in 2023. You can read it here https://github.com/board707/w80x_arduino/issues/33

But I don't know how it ended :)

Perhaps this person can be contacted for help.

Almost all the functions match the old SDK except for some recursive ones. I'm puzzled by this as well. The SDK for IOT is an open source project according to WinnerMicro's statement. Why they closed the RTOS part of the project is not quite clear to me

Hi. The lack of Serial.End() method is not critical in most cases. Its work is to deinitialize the hardware UART and release the controller pins that were connected to it.

It should be noted that the HardwareSerial class is static and calling the End() method does not free RAM. It is not difficult to add support for this method, but I would like to know how you want to use it.

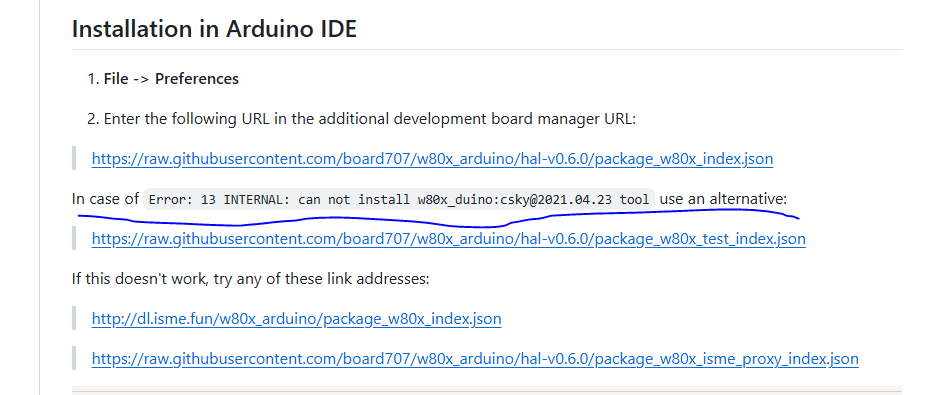

Hi. This problem was also stumbled upon by our users last year. The solution is described in https://github.com/board707/w80x_arduino/issues/39

Or see topic for internal Chine mirror http://ask.winnermicro.com/article/169.html

What SDK are you using?

I am currently adapting the W5500 into a w80x-arduino-iot project. Closer to the new year I will publish how to use WizNet chips together with LWIP library.

@feng201272195 But if you solve the problem in a different way, please tell here how you did it. It will be useful for everyone and interesting.

Thank you!

You don't need to do anything. Examine the code in the lv_port_disp.c file. When the USE_PSRAM parameter is enabled, memory for buffering is initialized in the lv_port_disp_init() function. You can play with the buffer size there

Which I2C device do you want to write or read data to?

Hello newbie! When adapting code for STM32 to use on the W806, you need to understand the differences in the hardware of these controllers. That is, the code can be divided into two parts - hardware dependent and hardware independent. You must rework the hardware-dependent part in relation to the features of the W806.

You may not need STM32-specific header files

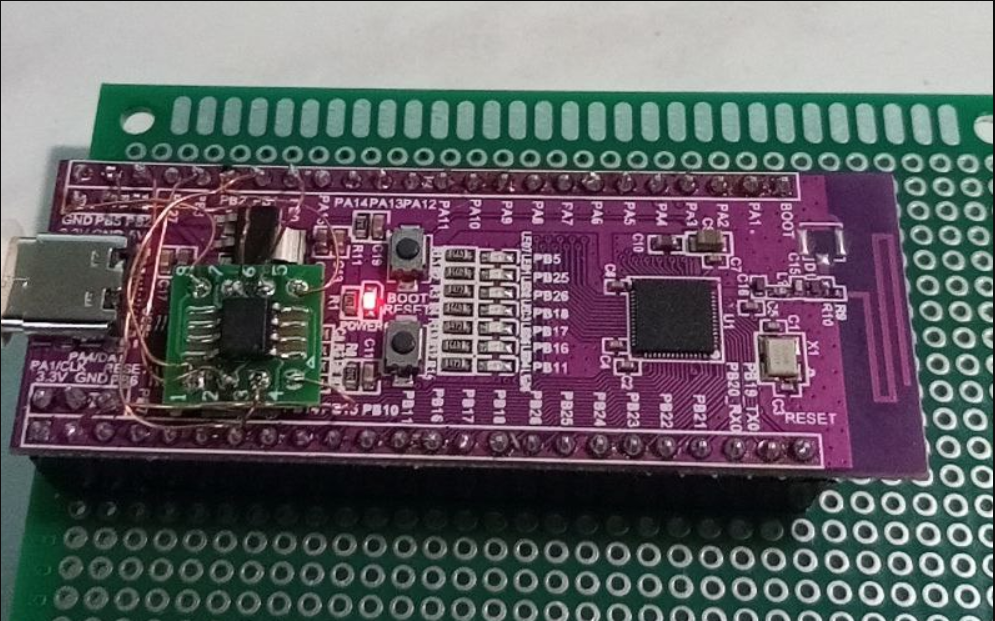

Compare your component installation with the W806 board circuit diagram. Maybe the USB-UART converter is not working

W801-KIT-V1.0-schematic.pdf

HLK-W806-V1-0-KIT.png

@1201 If your calculations require a large amount of RAM, use PSRAM for your arrays and variables. Solder the chip on top of the w801 board. When outputting to UART, reduce the transmission block size.

To help you we need to see the code. Show us how you use the EEPROM class

问 W806的玄铁CDS开发环境如何启用C99标准?